UNS R56400 Pipe Flanges, Titanium Grade 5 Flanges, Titanium Gr 5 Weld Neck Flanges, ASTM B348 Titanium Gr 5 Blind Flanges Manufacturer, Titanium Ti Alloy Gr 5 Slip On Flange Suppliers in India.

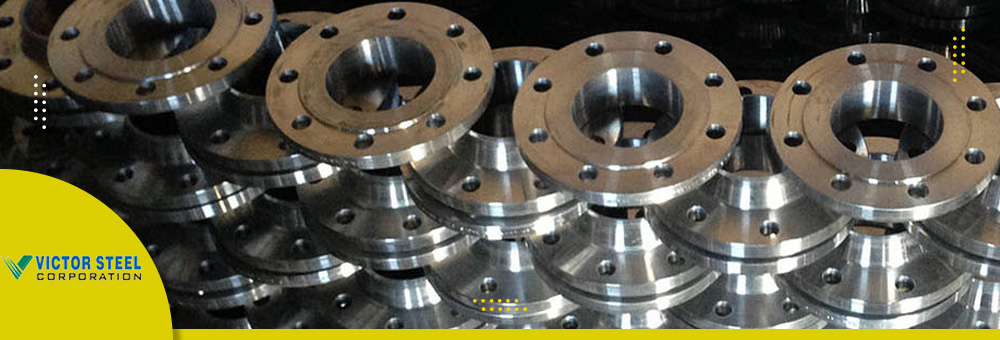

Victor Steel Corporation is a noticeable distributor of Titanium Grade 5 Pipe Flanges, which may be synthetic in a lot of sizes, materials and strain ratings. It has a specific deal by means of this is formed in a manner in order that or preservation crews understand whether or not a spade or spacer is established within side the pipeline. arc welding are recommended on these Titanium Gr 5 Threaded Flanges. Heavy duty machining equipment and tooling should be used in Titanium Gr 5 Weld Neck Flanges to minimize chatter or work – hardening of the alloy ahead of the cutting. Titanium Grade 5 is another perfect and preferred material for Flange manufacturing which is most durable and flexible. This Grade 5 of Titanium contains 0.05 % palladium, 0.1 % ruthenium, and 0.5% nickel which significantly increase corrosion resistance.

ANSI B16.5 Titanium Gr 5 Forged Flanges, Titanium Gr 5 WNRF Flange Dealer, ASME SB348 Titanium Grade 5 RTJ Flanges, Ti Alloy Gr 5 Socket Weld Flanges, DIN 3.7165 Threaded Flanges, Titanium Grade 5 Spectacle Blind Flanges, Titanium Ti Alloy Gr 5 Orifice Flange, Titanium Ti Alloy Gr 5 Lap Joint Flange, Titanium Gr 5 WNRF Flange Dealer, ASTM B348 Titanium Grade 5 SORF Flanges Manufacturer in Mumbai, India.

Table of Contents

- Standard Specification For Titanium Gr 5 Flanges

- Different Forms of Titanium Gr 5 Flanges

- Equivalent Grade Chart Of Titanium Gr 5 Flanges

- Manufacturing Standards / Pressure Rating of ASTM B564 Ti Alloy Grade 5 Pipe Flanges

- Chemical Composition Of Titanium Gr 5 Flanges

- Mechanical Properties Of Titanium Gr 5 Flanges

- Dimensions of Titanium Gr 5 Flanges

- Weight Chart of Titanium Gr 5 Flanges

- Keep Bulk Stock Of Titanium Gr 5 Flanges

- Titanium Gr 5 Flanges Export to below Mentioned Countries

- Titanium Gr 5 Flanges Application Area

Titanium Gr5 flanges is a chemical composition of aluminium, vanadium, iron, oxygen, titanium. Due to all these metals, it has several advantages. During machining, Titanium WNR 3.7165 Socket Weld Flanges work harden rapidly, generate excessive warmness in the course of slicing, weld to the slicing device floor and provide excessive resistance to metallic elimination for the cause that in their excessive shear strengths. Oxidation resistance of these flanges are excessive for non-stop carrier to 1500 Degree F, intermittent to 1800 Degree F.

When being synthetic they need to be crafted from a plate or forging specification, of basically the equal chemical composition for the reason of the mating alloys and piping involved. Ti 6Al/4V Forged Flanges are specifically used to offer flexibility in the course of operation and preservation. Titanium Grade 5 Flanges are made up of the most commonly used 90% titanium based alloy that is corrosion resistant, heat resistant and is strong. As a result, in addition to the usual length and specification referred to above, we also can layout and manufacture bespoke fittings to match our clients’ unique drawings or undertaking necessities.

Standard Specification For Titanium Gr 5 Flanges

| Specifications | ASTM B348 / ASME SB348 |

|---|---|

| Flanges size | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

| Flanges Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flange, ASME Flange, BS Flange, DIN Flange, EN Flange, GOST Flange. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Manufacturing Standards | ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange, ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE, BS Flange, EN Flange, API 6A Flange etc B.S: BS4504 , BS3293, BS1560, BS10 AS 2129: Table D; Table E; Table H ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48 ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 American standard (ANSI) German (DIN) British standard (BS) Any other specilised Flange DIN: DIN 2527, DIN 2566, DIN 2573, UNS S45367 Flange, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203;UNI2276 |

| Standard UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

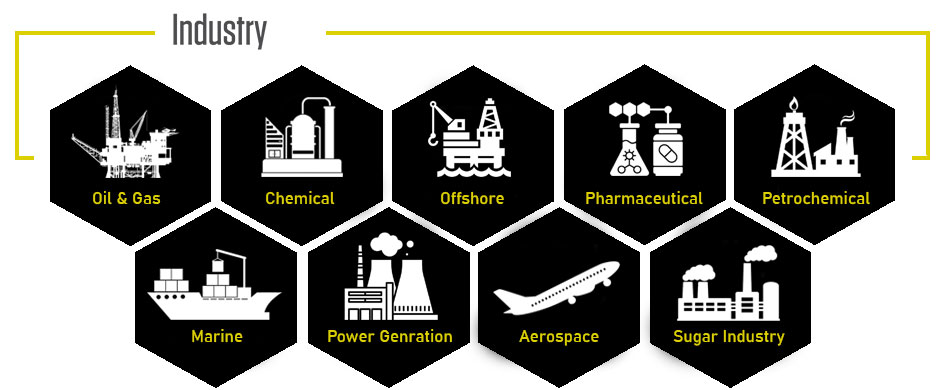

| Flanges uses & application | Nuclear power (mostly seamless). Petrochemicals and acids. Bitumen upgraders. Heavy oil refineries. |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175. | |

Check ASTM B348 Ti Alloy Grade 5 Ring Type Joint Flanges, DIN 3.7165 EN 1092 Ti Alloy Grade 5 Slip On Flange, PN40/ PN6/ PN10 Flanges, Titanium Alloy Grade 5 Flanges Manufacturer India, View Updated Titanium GR 5 Socket Weld Flanges Price List In India.

Different Forms of Titanium GR 5 Flanges

Equivalent Grade Chart Of Titanium Gr 5 Flanges

| STANDARD | WERKSTOFF NR. | UNS |

| Gr 5 | 3.7165 | R56400 |

Manufacturing Standards / Pressure Rating of ASTM B348 Ti Alloy Grade 5 Pipe Flanges

| ASME/ANSI B 16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Ring Type Joint Flange, Lap Joint Flange, Threaded Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Slip on Flange, Threaded Flange, Welding Neck Flange, |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Chemical Composition Of Titanium Gr 5 Pipe Flanges

| Grade | N | C | H | Fe | O | Al | V |

| Ti Grade 5 | 0.05 max | 0.10 max | 0.01 max | 0.40 max | 0.20 max | 5.50-6.75 | 3.50-4.50 |

Mechanical Properties Of Titanium Gr 5 Flanges

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Titanium Gr 5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000 , MPa – 950 | Psi – 128000 , MPa – 880 | 14 % |

Dimensions of Titanium Gr 5 Flanges

| Normal Pipe Size | Flanges Diameter ('O') |

Diameter of (B.C.) 'A' |

Diameter of (B.H.) 'D' |

Holes Number |

Flanges Wall Thickness 'C' |

Diameter (Flanges) at Weld Bevel | (Flanges) Diameter of Hub 'E' |

Length Of Through Hub | Bore ('B') | Diameter of (RF) R |

Depth of Socket Weld F |

Threading Length |

||||

| SORF/ SWRF (Y) |

WNRF (Y) |

Lap Joit (Y) |

SORF/ SWRF (B) |

Lap Joit (B) |

||||||||||||

| 1/2'' | 15 | 95.2 | 66.7 | 15.9 | 4 | 14.3 | 21.3 | 38.1 | 22.2 | 52.4 | 22.2 | 22.3 | 22.9 | 34.9 | 9.5 | 15.9 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/4'' | 20 | 117.5 | 82.5 | 19.0 | 4 | 15.9 | 26.7 | 47.6 | 25.4 | 57.1 | 25.4 | 27.7 | 28.2 | 42.9 | 11.1 | 15.9 |

| 1'' | 25 | 123.8 | 88.9 | 19.0 | 4 | 17.5 | 33.5 | 54.0 | 27.0 | 61.9 | 27.0 | 34.5 | 35.0 | 50.8 | 12.7 | 17.5 |

| 1 | 32 | 133.3 | 98.4 | 19.0 | 4 | 20.6 | 42.2 | 63.5 | 28.6 | 66.7 | 28.6 | 43.2 | 43.7 | 63.5 | 14.3 | 20.6 |

| 1 | 40 | 155.6 | 114.3 | 22.2 | 4 | 22.2 | 48.3 | 69.8 | 31.7 | 69.8 | 31.7 | 49.5 | 50.0 | 73.0 | 15.9 | 22.2 |

| 2'' | 50 | 165.1 | 127.0 | 19.0 | 8 | 25.4 | 60.4 | 84.1 | 36.5 | 73.0 | 36.5 | 62.0 | 62.5 | 92.1 | 17.5 | 25.4 |

| 2 | 65 | 190.5 | 149.2 | 22.2 | 8 | 28.6 | 73.1 | 100.0 | 41.3 | 79.4 | 41.3 | 74.7 | 75.4 | 104.8 | 19.0 | 28.6 |

| 3'' | 80 | 209.5 | 168.3 | 22.2 | 8 | 31.8 | 88.9 | 117.5 | 46.0 | 82.5 | 46.0 | 90.7 | 91.4 | 127.0 | - | 30.2 |

| 3 | 90 | 228.5 | 184.2 | 22.2 | 8 | 34.9 | 101.6 | 133.4 | 49.3 | 85.7 | 49.3 | 103.4 | 104.1 | 140.0 | - | 31.7 |

| 4'' | 100 | 273.0 | 215.9 | 25.4 | 8 | 38.1 | 114.3 | 152.4 | 54.0 | 101.6 | 54.0 | 116.1 | 116.8 | 157.2 | - | 33.3 |

| 5'' | 125 | 330.2 | 266.7 | 28.6 | 8 | 44.4 | 141.2 | 188.9 | 60.3 | 114.3 | 60.3 | 143.8 | 144.5 | 185.7 | - | 36.5 |

| 6'' | 150 | 355.6 | 292.1 | 28.6 | 12 | 47.6 | 168.4 | 222.2 | 66.7 | 117.5 | 66.7 | 170.7 | 171.4 | 215.9 | - | 39.7 |

| 8'' | 200 | 419.1 | 349.2 | 31.7 | 12 | 55.6 | 219.2 | 273.0 | 76.2 | 133.3 | 76.2 | 221.5 | 222.2 | 269.9 | - | 44.4 |

| 10'' | 250 | 508.0 | 431.8 | 34.9 | 16 | 63.5 | 273.0 | 342.9 | 85.7 | 152.4 | 111.2 | 276.3 | 277.4 | 323.8 | - | 49.2 |

| 12'' | 300 | 558.8 | 488.9 | 34.9 | 20 | 66.7 | 323.8 | 400.0 | 92.1 | 155.6 | 117.3 | 327.1 | 328.2 | 381.0 | - | 55.6 |

| 14'' | 350 | 603.2 | 527.0 | 38.1 | 20 | 69.9 | 355.6 | 431.8 | 93.7 | 165.1 | 127.0 | 359.1 | 360.2 | 412.7 | - | 57.1 |

| 16'' | 400 | 685.8 | 603.2 | 41.3 | 20 | 76.2 | 406.4 | 495.3 | 106.4 | 177.8 | 139.7 | 410.5 | 411.2 | 469.9 | - | 63.5 |

| 18'' | 450 | 742.9 | 654.0 | 44.4 | 24 | 82.6 | 457.2 | 546.1 | 117.5 | 184.1 | 152.4 | 461.8 | 462.3 | 533.4 | - | 68.3 |

| 20'' | 500 | 812.8 | 723.9 | 44.4 | 24 | 88.9 | 508.0 | 609.6 | 127.0 | 190.5 | 165.1 | 513.1 | 514.3 | 584.2 | - | 73.0 |

| 24'' | 600 | 939.8 | 838.2 | 50.8 | 24 | 101.6 | 609.6 | 717.5 | 139.7 | 203.2 | 184.1 | 615.9 | 615.9 | 692.1 | - | 82.5 |

Weight Chart of Titanium Gr 5 Flanges

| Pressure Class | Nominal Size Of Pipe (NPS) In Inch | Slip On (SORF) In Inch | Threaded (NPT) In Inch | Socket Weld (SWRF) In Inch | Lap Joint (LOOSE) In Inch | Blind (BLRF) In Inch | Weld Neck (WNRF) In Inch |

|---|---|---|---|---|---|---|---|

| Class 150 Flanges | ½ | 1 | 1 | 2 | 1 | 2 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 | |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 | |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 | |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 | |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 | |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 | |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 | |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 | |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 | |

| 5 | 15 | 15 | 15 | 15 | 20 | 21 | |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 | |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 | |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 | |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 | |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 | |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 | |

| 18 | 130 | 130 | 130 | 160 | 220 | 165 | |

| 20 | 165 | 165 | 165 | 195 | 285 | 197 | |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 | |

| 24 | 220 | 220 | 220 | 275 | 430 | 268 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 300 Flanges | ½ | 2 | 2 | 3 | 2 | 2 | 2 |

| ¾ | 3 | 3 | 3 | 3 | 3 | 3 | |

| 1 | 3 | 3 | 3 | 3 | 4 | 4 | |

| 1¼ | 4.5 | 4.5 | 4 | 4.5 | 6 | 5 | |

| 1½ | 6.5 | 6.5 | 6 | 6.5 | 7 | 7 | |

| 2 | 7 | 7 | 7 | 7 | 8 | 9 | |

| 2½ | 10 | 10 | 10 | 10 | 12 | 12 | |

| 3 | 13 | 14 | 13 | 14.5 | 16 | 18 | |

| 3½ | 17 | 17 | 17 | 17 | 21 | 20 | |

| 4 | 23.5 | 24 | 22 | 24 | 28 | 26.5 | |

| 5 | 29 | 31 | 28 | 28 | 37 | 36 | |

| 6 | 39 | 39 | 39 | 39 | 50 | 45 | |

| 8 | 58 | 58 | 58 | 58 | 81 | 69 | |

| 10 | 81 | 81 | 81 | 91 | 124 | 100 | |

| 12 | 115 | 115 | 115 | 140 | 185 | 142 | |

| 14 | 165 | 165 | 165 | 190 | 250 | 206 | |

| 16 | 210 | 220 | 190 | 234 | 315 | 250 | |

| 18 | 253 | 280 | 250 | 305 | 414 | 320 | |

| 20 | 315 | 325 | 315 | 375 | 515 | 400 | |

| 22 | 370 | 370 | 370 | 435 | 640 | 465 | |

| 24 | 490 | 490 | 475 | 550 | 800 | 580 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 400 Flanges | ½ | 2 | 2 | 2 | 2 | 2 | 3 |

| ¾ | 3 | 3 | 3 | 3 | 3 | 3.5 | |

| 1 | 3.5 | 3.5 | 3.5 | 3.5 | 4 | 4 | |

| 1¼ | 4.5 | 4.5 | 4.5 | 4.5 | 6 | 4.5 | |

| 1½ | 6.5 | 6.5 | 6.5 | 6.5 | 8 | 8 | |

| 2 | 8 | 8 | 8 | 8 | 10 | 10 | |

| 2½ | 12 | 12 | 12 | 11 | 15 | 14 | |

| 3 | 15 | 15 | 15 | 14 | 20 | 18 | |

| 3½ | 21 | 21 | 21 | 20 | 29 | 26 | |

| 4 | 26 | 26 | 26 | 25 | 33 | 35 | |

| 5 | 31 | 31 | 31 | 29 | 44 | 43 | |

| 6 | 44 | 44 | 44 | 42 | 61 | 57 | |

| 8 | 67 | 67 | 67 | 64 | 100 | 89 | |

| 10 | 91 | 91 | 91 | 110 | 155 | 125 | |

| 12 | 130 | 130 | 130 | 152 | 226 | 175 | |

| 14 | 191 | 191 | 191 | 210 | 310 | 233 | |

| 16 | 253 | 253 | 253 | 280 | 398 | 295 | |

| 18 nbsp; | 310 | 310 | 310 | 345 | 502 | 360 | |

| 20 | 378 | 378 | 378 | 420 | 621 | 445 | |

| 22 | 405 | 405 | 405 | 455 | 720 | 505 | |

| 24 | 539 | 539 | 539 | 615 | 936 | 640 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class Gr 5 Flanges | ½ | 2 | 2 | 2 | 2 | 3 | 3 |

| ¾ | 3 | 3 | 3 | 3 | 4 | 4 | |

| 1 | 4 | 4 | 4 | 4 | 4 | 4 | |

| 1¼ | 5 | 5 | 5 | 5 | 6 | 6 | |

| 1½ | 7 | 7 | 7 | 7 | 8 | 8 | |

| 2 | 9 | 9 | 9 | 9 | 10 | 12 | |

| 2½ | 13 | 13 | 13 | 12 | 15 | 18 | |

| 3 | 16 | 16 | 16 | 15 | 20 | 23 | |

| 3½ | 21 | 21 | 21 | 20 | 29 | 26 | |

| 4 | 37 | 37 | 37 | 36 | 41 | 42 | |

| 5 | 63 | 63 | 63 | 63 | 68 | 68 | |

| 6 | 80 | 80 | 80 | 78 | 86 | 81 | |

| 8 | 115 | 15 | 15 | 112 | 140 | 120 | |

| 10 | 177 | 177 | 177 | 195 | 231 | 190 | |

| 12 | 215 | 215 | 215 | 240 | 295 | 226 | |

| 14 | 259 | 259 | 259 | 290 | 378 | 347 | |

| 16 | 366 | 366 | 366 | 400 | 527 | 481 | |

| 18 | 476 | 476 | 476 | 469 | 665 | 555 | |

| 20 | 612 | 612 | 612 | 604 | 855 | 690 | |

| 22 | 590 | 590 | 590 | 670 | 1000 | 720 | |

| 24 | 876 | 876 | 876 | 866 | 1250 | 977 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 900 Flanges | ½ | 6 | 6 | 6 | 6 | 4 | 7 |

| ¾ | 6 | 6 | 6 | 6 | 6 | 7 | |

| 1 | 7.5 | 7.5 | 7.5 | 7.5 | 9 | 8.5 | |

| 1¼ | 10 | 10 | 10 | 10 | 10 | 10 | |

| 1½ | 14 | 14 | 14 | 14 | 14 | 14 | |

| 2 | 22 | 22 | 22 | 21 | 25 | 24 | |

| 2½ | 31 | 31 | 31 | 25 | 32 | 31 | |

| 3 | 36 | 36 | 36 | 29 | 35 | 36 | |

| 4 | 53 | 53 | 53 | 51 | 54 | 53 | |

| 5 | 83 | 83 | 83 | 81 | 87 | 86 | |

| 6 | 110 | 110 | 110 | 105 | 115 | 110 | |

| 8 | 172 | 172 | 172 | 190 | 200 | 187 | |

| 10 | 245 | 245 | 245 | 277 | 290 | 268 | |

| 12 | 326 | 326 | 326 | 371 | 415 | 372 | |

| 14 | 400 | 400 | 400 | 415 | 520 | 562 | |

| 16 | 459 | 459 | 459 | 488 | 619 | 685 | |

| 18 | 647 | 647 | 647 | 670 | 880 | 924 | |

| 20 | 792 | 792 | 792 | 868 | 1107 | 1164 | |

| 24 | 1480 | 1480 | 1480 | 1659 | 2099 | 2107 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 1500 Flanges | ½ | 6 | 6 | 6 | 6 | 4 | 7 |

| ¾ | 6 | 6 | 6 | 6 | 6 | 7 | |

| 1 | 8 | 8 | 8 | 8 | 9 | 9 | |

| 1¼ | 10 | 10 | 10 | 10 | 10 | 10 | |

| 1½ | 14 | 14 | 14 | 14 | 14 | 14 | |

| 2 | 25 | 25 | 25 | 25 | 25 | 25 | |

| 2½ | 36 | 36 | 36 | 35 | 35 | 36 | |

| 3 | 48 | 48 | 48 | 47 | 48 | 48 | |

| 4 | 73 | 73 | 73 | 75 | 73 | 73 | |

| 5 | 132 | 132 | 132 | 140 | 140 | 132 | |

| 6 | 165 | 165 | 165 | 170 | 160 | 165 | |

| 8 | 260 | 260 | 260 | 286 | 302 | 275 | |

| 10 | 436 | 436 | 436 | 485 | 510 | 455 | |

| 12 | 667 | 667 | 667 | 749 | 775 | 690 | |

| 14 | 940 | 940 | 940 | 890 | 975 | 940 | |

| 16 | 1250 | 1250 | 1250 | 1250 | 1300 | 1250 | |

| 18 | 1625 | 1625 | 1625 | 1475 | 1750 | 1625 | |

| 20 | 2050 | 2050 | 2050 | 1775 | 2225 | 2050 | |

| 24 | 2825 | 2825 | 2825 | 2825 | 3625 | 3325 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 2500 Flanges | ½ | …. | 7 | …. | 7 | 7 | 8 |

| ¾ | …. | 9 | …. | 8 | 10 | 9 | |

| 1 | …. | 12 | …. | 12 | 12 | 13 | |

| 1¼ | …. | 18 | …. | 17 | 18 | 20 | |

| 1½ | …. | 25 | …. | 24 | 25 | 28 | |

| 2 | …. | 38 | …. | 37 | 39 | 42 | |

| 2½ | …. | 55 | …. | 53 | 56 | 52 | |

| 3 | …. | 83 | …. | 80 | 86 | 94 | |

| 4 | …. | 127 | …. | 122 | 133 | 146 | |

| 5 | …. | 210 | …. | 204 | 223 | 244 | |

| 6 | …. | 323 | …. | 314 | 345 | 378 | |

| 8 | …. | 485 | …. | 471 | 533 | 576 | |

| 10 | …. | 925 | …. | 897 | 1025 | 1068 | |

| 12 | …. | 1300 | …. | 1262 | 1464 | 1608 |

Keep Bulk Stock Of Titanium Gr 5 Flanges

- Titanium Gr 5 BS 4504 Flanges

- ASTM B348 Titanium Alloy Grade 5 Lap Joint Flanges

- ASTM B348 Hastelloy Grade 5 Flanges

- Ti Alloy Grade 5 Threaded Flanges

- Titanium Grade 5 Orifice Flanges

- Ti Alloy Grade 5 Raised Face Flanges Stockist

- Titanium Ti Alloy Loose Flanges

- Titanium Gr 5 Slip on Flanges

- ASTM B348 Titanium Ti Alloy Garde 5 BLRF Flange Flanges

- Ti Alloy Grade 5 Pipe Flanges

- UNS R56400 Flanges Supplier in Mumbai

- ASTM B348 Titanium Grade 5 Square Flanges

- ASTM B564 Titanium Gr 5 Screwed Flanges

- Gr 5 Titanium Blind Flange

- ASME B16.5 Titanium Gr 5 Socket weld Flanges

- Ti Alloy Grade 5 Long Weld Neck Flanges

- Titanium Gr 5 Forged Flanges

- Ti Alloy Grade 5 Welding Neck Flanges

- ANSI B16.5 Alloy Grade 5 RTJ Flanges

- ASME SB564 Alloy Grade 5 SWRF Flange

- Ti Alloy Grade 5 Male & Female Flanges

- Titanium Grade 5 PN 10 Flanges

- Titanium Grade 5 Large Diameter Flanges Exporter

- Ti Alloy Grade Lap Joint Flanges

- Titanium Ti Alloy Grade 5 Nippo Flange Manufacturer

- Titanium Grade 5 High Hub Blind Flanges

- Titanium Gr 5 Spectacle Blind Flanges

- Titanium Ti Alloy Gr 5 Plate Flanges

- Ti Alloy Grade 5 AWWA C207 Flange Manufacturer in Mumbai, India

- Titanium Gr 5 SORF Flanges

- Titanium Gr 5 Raised Face Flanges

- Ti Alloy Grade 5 Ring Type Joint Flanges

- Titanium Ti Alloy Grade 5 Reducing Flanges

- Titanium Gr 5 Reducing Flanges Price List

- Titanium Gr 5 WNRF Flange

- Ti Alloy Grade 5 Expander Flanges

- DIN 3.7165 Orifice Flange

- Titanium Ti Alloy Grade 5 BLRF Flange Supplier

Titanium Gr 5 Flanges Export to below Mentioned Countries

MIDDLE EAST : Saudi Arabia, Qatar, Bahrain, Oman, Kuwait, Turkey, Yemen, Syria, Jordan, Cyprus

AFRICA : Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Equatorial Guinea, the Republic Of Congo, Gabon

NORTH AMERICA : US, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark

EUROPE : Russia, Norway, Germany, France, Italy, UK, Spain, Ukraine, Netherlands, Belgium, Greece, Czech Republic, Portugal, Hungary Albania, Austria, Switzerland, Slovakia Finland, Ireland Croatia, Slovenia, Malta

ASIA : Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh,Myanmar, Taiwan, Cambodia

SOUTH AMERICA : Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay