UNS N08020 Pipe Flanges, Alloy 20 Flanges, ASTM B462 Alloy 20 Blind Flanges Manufacturer, Incoloy Alloy 20 Weld Neck Flanges, Carpenter Alloy 20 Slip On Flange Suppliers in India.

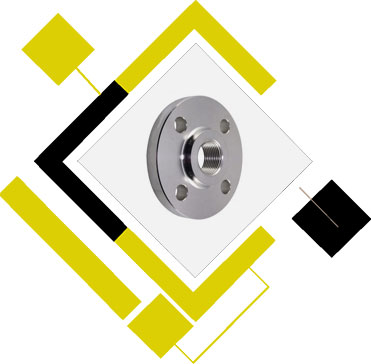

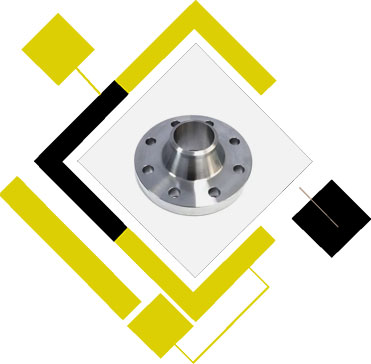

Victor Steel Corporation is a widely held stockist of Alloy 20 Pipe Flanges, which is nicely-desirable for carrier in severe environments subjected to stress and warmth. The weldability of metal castings is generally depending on its chemical composition in addition to its warmth treatment. UNS N08020 Threaded Flanges is regularly utilized by industries that use forged materials uncovered to severe warmth due to this capability. By means of having titanium inert fueloline welding, producers can steady the weld location from water vapor and oxygen. Alloy 20 flanges provide good performance in hot sulfuric acid, specifically they offer good resistance to stress-corrosion cracking in boiling sulfuric acid at specific range of 20% to 40% concentration, as well as general sulfuric acid resistance.

Nickel Alloy 20 Flanges, ASME SB462 20 RTJ Flanges, Alloy 20 WNRF Flange Dealer, Alloy 20 Orifice Flange, ASME SA182 304 RTJ Flanges, ANSI B16.5 Alloy 20 Forged Flanges, DIN 2.4660 Threaded Flanges, Carpenter® Alloy 20 Orifice Flange, ASTM B462 NiCr20CuMo Socket weld Flanges, ASME SB462 Carpenter 20 SORF Flanges Manufacturer in Mumbai, India.

Table of Contents

- Standard Specification For Alloy 20 Flanges

- Different Forms of Alloy 20 Flanges

- Equivalent Grade Chart Of Alloy 20 Flanges

- International Standards of ASTM B462 20 Flanges

- Chemical Composition Of Alloy 20 Flanges

- Mechanical Properties Of Alloy 20 Flanges

- Dimensions of Alloy 20 Flanges

- Tolerance Chart of Alloy 20 Flanges

- Keep Bulk Stock Of Alloy 20 Flanges

- Alloy 20 Flanges Export to below Mentioned Countries

- Alloy 20 Flanges Application Area

According to steel experts, this kind is beneficial in welding portions of alloy together. Another true a part of the use of alloy is that it is able to additionally be welded by means of having different metals. For instance, maximum welding industries use metal to provide long lasting and warmth-resistance steel. Alloy 20 Reducing Flanges primarily contain elements such as nickel, iron and chromium in their alloy with additions of metal elements like molybdenum and copper. We are a manufacturer, trader, stockist, supplier and exporter of ASTM B462 Alloy 20 Flanges that are not only compatible for sulphuric acid related industries but also to any industry dealing with a host of toxic acids.

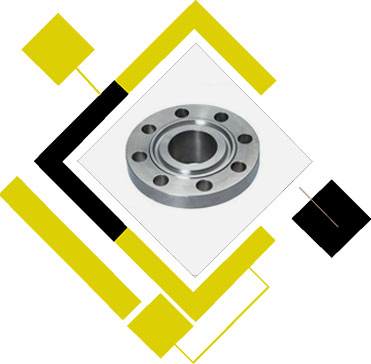

The TIG approach gives the welder to benefit greater manage over the materials. Corrosion is certainly considered one among the most important and maximum not unusual place troubles confronted via way of means of industries the usage of forged materials. Hence, these Alloy 20 Ring Type Joint Flanges are nonetheless extensively utilized by forging industries to provide excellent and oxidation-resistant end products.The chemical composition of Alloy 20 Flanges will mainly include nickel, chromium, and iron, along with some additional elements like molybdenum and copper.

Standard Specification For Alloy 20 Flanges

| Specifications | ASTM B462 / ASME SB462 |

|---|---|

| Flanges size | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

| Flanges Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flange, ASME Flange, BS Flange, DIN Flange, EN Flange, GOST Flange. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Manufacturing Standards | ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange, ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE, BS Flange, EN Flange, API 6A Flange etc B.S: BS4504 , BS3293, BS1560, BS10 AS 2129: Table D; Table E; Table H ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48 ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 American standard (ANSI) German (DIN) British standard (BS) Any other specilised Flange DIN: DIN 2527, DIN 2566, DIN 2573, UNS S45367 Flange, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203;UNI2276 |

| Standard UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

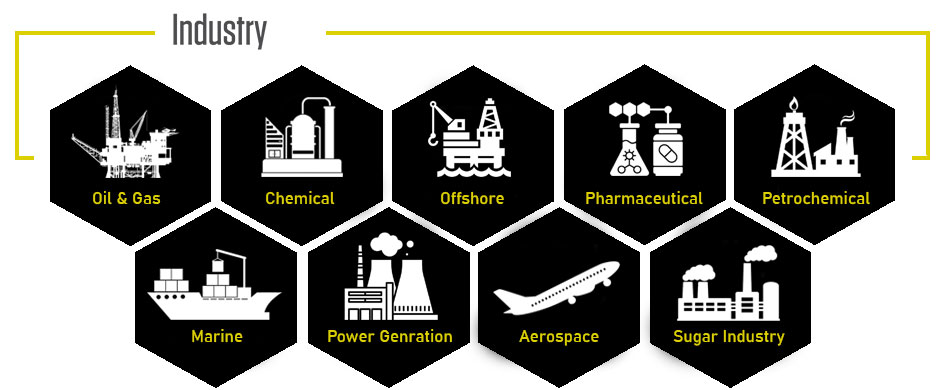

| Flanges uses & application | Nuclear power (mostly seamless). Petrochemicals and acids. Bitumen upgraders. Heavy oil refineries. |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175. | |

Check ASTM B462 20 Ring Type Joint Flanges, DIN 2.4660 EN 1092 1 Alloy 20 Slip On Flange, PN40/ PN6/ PN10 Flanges, 20 Alloy Flanges Manufacturer India, View Updated Stainless Alloy 20 Weld Neck Flanges Price List In India.

Different Forms of Alloy 20 Flanges

Equivalent Grade Chart Of Alloy 20 Flanges

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Alloy 20 | 2.4660 | N08020 | - | - | - | Z2NCUD31-20AZ | NiCr20CuMo |

Manufacturing Standards / Pressure Rating of ASTM A182 Alloy 20 Pipe Flanges

| ASME/ANSI B 16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Ring Type Joint Flange, Lap Joint Flange, Threaded Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Slip on Flange, Threaded Flange, Welding Neck Flange, |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Chemical Composition Of Alloy 20 Pipe Flanges

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| Alloy 20 | 0.07 max | 2 max | 1.0 max | 0.045 max | 0.035 max | 19 - 21 | 2 - 3 | 32 - 38 | - |

Mechanical Properties Of Alloy 20 Flanges

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1443 °C (2430 °F) | Psi – 80000 , MPa – 551 | Psi – 35000 , MPa – 241 | 30 % |

Dimensions of Alloy 20 Flanges

| Normal Pipe Size | Flanges Diameter ('O') |

Diameter of (B.C.) 'A' |

Diameter of (B.H.) 'D' |

Holes Number |

Flanges Wall Thickness 'C' |

Diameter (Flanges) at Weld Bevel | (Flanges) Diameter of Hub 'E' |

Length Of Through Hub | Bore ('B') | Diameter of (RF) R |

Depth of Socket Weld F |

Threading Length |

||||

| SORF/ SWRF (Y) |

WNRF (Y) |

Lap Joit (Y) |

SORF/ SWRF (B) |

Lap Joit (B) |

||||||||||||

| 1/2'' | 15 | 95.2 | 66.7 | 15.9 | 4 | 14.3 | 21.3 | 38.1 | 22.2 | 52.4 | 22.2 | 22.3 | 22.9 | 34.9 | 9.5 | 15.9 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/4'' | 20 | 117.5 | 82.5 | 19.0 | 4 | 15.9 | 26.7 | 47.6 | 25.4 | 57.1 | 25.4 | 27.7 | 28.2 | 42.9 | 11.1 | 15.9 |

| 1'' | 25 | 123.8 | 88.9 | 19.0 | 4 | 17.5 | 33.5 | 54.0 | 27.0 | 61.9 | 27.0 | 34.5 | 35.0 | 50.8 | 12.7 | 17.5 |

| 1 | 32 | 133.3 | 98.4 | 19.0 | 4 | 20.6 | 42.2 | 63.5 | 28.6 | 66.7 | 28.6 | 43.2 | 43.7 | 63.5 | 14.3 | 20.6 |

| 1 | 40 | 155.6 | 114.3 | 22.2 | 4 | 22.2 | 48.3 | 69.8 | 31.7 | 69.8 | 31.7 | 49.5 | 50.0 | 73.0 | 15.9 | 22.2 |

| 2'' | 50 | 165.1 | 127.0 | 19.0 | 8 | 25.4 | 60.4 | 84.1 | 36.5 | 73.0 | 36.5 | 62.0 | 62.5 | 92.1 | 17.5 | 25.4 |

| 2 | 65 | 190.5 | 149.2 | 22.2 | 8 | 28.6 | 73.1 | 100.0 | 41.3 | 79.4 | 41.3 | 74.7 | 75.4 | 104.8 | 19.0 | 28.6 |

| 3'' | 80 | 209.5 | 168.3 | 22.2 | 8 | 31.8 | 88.9 | 117.5 | 46.0 | 82.5 | 46.0 | 90.7 | 91.4 | 127.0 | - | 30.2 |

| 3 | 90 | 228.5 | 184.2 | 22.2 | 8 | 34.9 | 101.6 | 133.4 | 49.3 | 85.7 | 49.3 | 103.4 | 104.1 | 140.0 | - | 31.7 |

| 4'' | 100 | 273.0 | 215.9 | 25.4 | 8 | 38.1 | 114.3 | 152.4 | 54.0 | 101.6 | 54.0 | 116.1 | 116.8 | 157.2 | - | 33.3 |

| 5'' | 125 | 330.2 | 266.7 | 28.6 | 8 | 44.4 | 141.2 | 188.9 | 60.3 | 114.3 | 60.3 | 143.8 | 144.5 | 185.7 | - | 36.5 |

| 6'' | 150 | 355.6 | 292.1 | 28.6 | 12 | 47.6 | 168.4 | 222.2 | 66.7 | 117.5 | 66.7 | 170.7 | 171.4 | 215.9 | - | 39.7 |

| 8'' | 200 | 419.1 | 349.2 | 31.7 | 12 | 55.6 | 219.2 | 273.0 | 76.2 | 133.3 | 76.2 | 221.5 | 222.2 | 269.9 | - | 44.4 |

| 10'' | 250 | 508.0 | 431.8 | 34.9 | 16 | 63.5 | 273.0 | 342.9 | 85.7 | 152.4 | 111.2 | 276.3 | 277.4 | 323.8 | - | 49.2 |

| 12'' | 300 | 558.8 | 488.9 | 34.9 | 20 | 66.7 | 323.8 | 400.0 | 92.1 | 155.6 | 117.3 | 327.1 | 328.2 | 381.0 | - | 55.6 |

| 14'' | 350 | 603.2 | 527.0 | 38.1 | 20 | 69.9 | 355.6 | 431.8 | 93.7 | 165.1 | 127.0 | 359.1 | 360.2 | 412.7 | - | 57.1 |

| 16'' | 400 | 685.8 | 603.2 | 41.3 | 20 | 76.2 | 406.4 | 495.3 | 106.4 | 177.8 | 139.7 | 410.5 | 411.2 | 469.9 | - | 63.5 |

| 18'' | 450 | 742.9 | 654.0 | 44.4 | 24 | 82.6 | 457.2 | 546.1 | 117.5 | 184.1 | 152.4 | 461.8 | 462.3 | 533.4 | - | 68.3 |

| 20'' | 500 | 812.8 | 723.9 | 44.4 | 24 | 88.9 | 508.0 | 609.6 | 127.0 | 190.5 | 165.1 | 513.1 | 514.3 | 584.2 | - | 73.0 |

| 24'' | 600 | 939.8 | 838.2 | 50.8 | 24 | 101.6 | 609.6 | 717.5 | 139.7 | 203.2 | 184.1 | 615.9 | 615.9 | 692.1 | - | 82.5 |

Weight Chart of Alloy 20 Flanges

| Pressure Class | Nominal Size Of Pipe (NPS) In Inch | Slip On (SORF) In Inch | Threaded (NPT) In Inch | Socket Weld (SWRF) In Inch | Lap Joint (LOOSE) In Inch | Blind (BLRF) In Inch | Weld Neck (WNRF) In Inch |

|---|---|---|---|---|---|---|---|

| Class 150 Flanges | ½ | 1 | 1 | 2 | 1 | 2 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 | |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 | |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 | |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 | |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 | |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 | |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 | |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 | |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 | |

| 5 | 15 | 15 | 15 | 15 | 20 | 21 | |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 | |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 | |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 | |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 | |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 | |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 | |

| 18 | 130 | 130 | 130 | 160 | 220 | 165 | |

| 20 | 165 | 165 | 165 | 195 | 285 | 197 | |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 | |

| 24 | 220 | 220 | 220 | 275 | 430 | 268 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 300 Flanges | ½ | 2 | 2 | 3 | 2 | 2 | 2 |

| ¾ | 3 | 3 | 3 | 3 | 3 | 3 | |

| 1 | 3 | 3 | 3 | 3 | 4 | 4 | |

| 1¼ | 4.5 | 4.5 | 4 | 4.5 | 6 | 5 | |

| 1½ | 6.5 | 6.5 | 6 | 6.5 | 7 | 7 | |

| 2 | 7 | 7 | 7 | 7 | 8 | 9 | |

| 2½ | 10 | 10 | 10 | 10 | 12 | 12 | |

| 3 | 13 | 14 | 13 | 14.5 | 16 | 18 | |

| 3½ | 17 | 17 | 17 | 17 | 21 | 20 | |

| 4 | 23.5 | 24 | 22 | 24 | 28 | 26.5 | |

| 5 | 29 | 31 | 28 | 28 | 37 | 36 | |

| 6 | 39 | 39 | 39 | 39 | 50 | 45 | |

| 8 | 58 | 58 | 58 | 58 | 81 | 69 | |

| 10 | 81 | 81 | 81 | 91 | 124 | 100 | |

| 12 | 115 | 115 | 115 | 140 | 185 | 142 | |

| 14 | 165 | 165 | 165 | 190 | 250 | 206 | |

| 16 | 210 | 220 | 190 | 234 | 315 | 250 | |

| 18 | 253 | 280 | 250 | 305 | 414 | 320 | |

| 20 | 315 | 325 | 315 | 375 | 515 | 400 | |

| 22 | 370 | 370 | 370 | 435 | 640 | 465 | |

| 24 | 490 | 490 | 475 | 550 | 800 | 580 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 400 Flanges | ½ | 2 | 2 | 2 | 2 | 2 | 3 |

| ¾ | 3 | 3 | 3 | 3 | 3 | 3.5 | |

| 1 | 3.5 | 3.5 | 3.5 | 3.5 | 4 | 4 | |

| 1¼ | 4.5 | 4.5 | 4.5 | 4.5 | 6 | 4.5 | |

| 1½ | 6.5 | 6.5 | 6.5 | 6.5 | 8 | 8 | |

| 2 | 8 | 8 | 8 | 8 | 10 | 10 | |

| 2½ | 12 | 12 | 12 | 11 | 15 | 14 | |

| 3 | 15 | 15 | 15 | 14 | 20 | 18 | |

| 3½ | 21 | 21 | 21 | 20 | 29 | 26 | |

| 4 | 26 | 26 | 26 | 25 | 33 | 35 | |

| 5 | 31 | 31 | 31 | 29 | 44 | 43 | |

| 6 | 44 | 44 | 44 | 42 | 61 | 57 | |

| 8 | 67 | 67 | 67 | 64 | 100 | 89 | |

| 10 | 91 | 91 | 91 | 110 | 155 | 125 | |

| 12 | 130 | 130 | 130 | 152 | 226 | 175 | |

| 14 | 191 | 191 | 191 | 210 | 310 | 233 | |

| 16 | 253 | 253 | 253 | 280 | 398 | 295 | |

| 18 nbsp; | 310 | 310 | 310 | 345 | 502 | 360 | |

| 20 | 378 | 378 | 378 | 420 | 621 | 445 | |

| 22 | 405 | 405 | 405 | 455 | 720 | 505 | |

| 24 | 539 | 539 | 539 | 615 | 936 | 640 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 600 Flanges | ½ | 2 | 2 | 2 | 2 | 3 | 3 |

| ¾ | 3 | 3 | 3 | 3 | 4 | 4 | |

| 1 | 4 | 4 | 4 | 4 | 4 | 4 | |

| 1¼ | 5 | 5 | 5 | 5 | 6 | 6 | |

| 1½ | 7 | 7 | 7 | 7 | 8 | 8 | |

| 2 | 9 | 9 | 9 | 9 | 10 | 12 | |

| 2½ | 13 | 13 | 13 | 12 | 15 | 18 | |

| 3 | 16 | 16 | 16 | 15 | 20 | 23 | |

| 3½ | 21 | 21 | 21 | 20 | 29 | 26 | |

| 4 | 37 | 37 | 37 | 36 | 41 | 42 | |

| 5 | 63 | 63 | 63 | 63 | 68 | 68 | |

| 6 | 80 | 80 | 80 | 78 | 86 | 81 | |

| 8 | 115 | 15 | 15 | 112 | 140 | 120 | |

| 10 | 177 | 177 | 177 | 195 | 231 | 190 | |

| 12 | 215 | 215 | 215 | 240 | 295 | 226 | |

| 14 | 259 | 259 | 259 | 290 | 378 | 347 | |

| 16 | 366 | 366 | 366 | 400 | 527 | 481 | |

| 18 | 476 | 476 | 476 | 469 | 665 | 555 | |

| 20 | 612 | 612 | 612 | 604 | 855 | 690 | |

| 22 | 590 | 590 | 590 | 670 | 1000 | 720 | |

| 24 | 876 | 876 | 876 | 866 | 1250 | 977 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 900 Flanges | ½ | 6 | 6 | 6 | 6 | 4 | 7 |

| ¾ | 6 | 6 | 6 | 6 | 6 | 7 | |

| 1 | 7.5 | 7.5 | 7.5 | 7.5 | 9 | 8.5 | |

| 1¼ | 10 | 10 | 10 | 10 | 10 | 10 | |

| 1½ | 14 | 14 | 14 | 14 | 14 | 14 | |

| 2 | 22 | 22 | 22 | 21 | 25 | 24 | |

| 2½ | 31 | 31 | 31 | 25 | 32 | 31 | |

| 3 | 36 | 36 | 36 | 29 | 35 | 36 | |

| 4 | 53 | 53 | 53 | 51 | 54 | 53 | |

| 5 | 83 | 83 | 83 | 81 | 87 | 86 | |

| 6 | 110 | 110 | 110 | 105 | 115 | 110 | |

| 8 | 172 | 172 | 172 | 190 | 200 | 187 | |

| 10 | 245 | 245 | 245 | 277 | 290 | 268 | |

| 12 | 326 | 326 | 326 | 371 | 415 | 372 | |

| 14 | 400 | 400 | 400 | 415 | 520 | 562 | |

| 16 | 459 | 459 | 459 | 488 | 619 | 685 | |

| 18 | 647 | 647 | 647 | 670 | 880 | 924 | |

| 20 | 792 | 792 | 792 | 868 | 1107 | 1164 | |

| 24 | 1480 | 1480 | 1480 | 1659 | 2099 | 2107 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 1500 Flanges | ½ | 6 | 6 | 6 | 6 | 4 | 7 |

| ¾ | 6 | 6 | 6 | 6 | 6 | 7 | |

| 1 | 8 | 8 | 8 | 8 | 9 | 9 | |

| 1¼ | 10 | 10 | 10 | 10 | 10 | 10 | |

| 1½ | 14 | 14 | 14 | 14 | 14 | 14 | |

| 2 | 25 | 25 | 25 | 25 | 25 | 25 | |

| 2½ | 36 | 36 | 36 | 35 | 35 | 36 | |

| 3 | 48 | 48 | 48 | 47 | 48 | 48 | |

| 4 | 73 | 73 | 73 | 75 | 73 | 73 | |

| 5 | 132 | 132 | 132 | 140 | 140 | 132 | |

| 6 | 165 | 165 | 165 | 170 | 160 | 165 | |

| 8 | 260 | 260 | 260 | 286 | 302 | 275 | |

| 10 | 436 | 436 | 436 | 485 | 510 | 455 | |

| 12 | 667 | 667 | 667 | 749 | 775 | 690 | |

| 14 | 940 | 940 | 940 | 890 | 975 | 940 | |

| 16 | 1250 | 1250 | 1250 | 1250 | 1300 | 1250 | |

| 18 | 1625 | 1625 | 1625 | 1475 | 1750 | 1625 | |

| 20 | 2050 | 2050 | 2050 | 1775 | 2225 | 2050 | |

| 24 | 2825 | 2825 | 2825 | 2825 | 3625 | 3325 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 2500 Flanges | ½ | …. | 7 | …. | 7 | 7 | 8 |

| ¾ | …. | 9 | …. | 8 | 10 | 9 | |

| 1 | …. | 12 | …. | 12 | 12 | 13 | |

| 1¼ | …. | 18 | …. | 17 | 18 | 20 | |

| 1½ | …. | 25 | …. | 24 | 25 | 28 | |

| 2 | …. | 38 | …. | 37 | 39 | 42 | |

| 2½ | …. | 55 | …. | 53 | 56 | 52 | |

| 3 | …. | 83 | …. | 80 | 86 | 94 | |

| 4 | …. | 127 | …. | 122 | 133 | 146 | |

| 5 | …. | 210 | …. | 204 | 223 | 244 | |

| 6 | …. | 323 | …. | 314 | 345 | 378 | |

| 8 | …. | 485 | …. | 471 | 533 | 576 | |

| 10 | …. | 925 | …. | 897 | 1025 | 1068 | |

| 12 | …. | 1300 | …. | 1262 | 1464 | 1608 |

Keep Bulk Stock Of Alloy 20 Flanges

- Carpenter® Alloy 20 Forged Flanges

- NiCr20CuMo Long Weld Neck Flanges

- Incoloy Alloy JIS B2220 Flange

- ASTM B462 Alloy 20 Square Flanges

- Alloy 20 Threaded Flanges

- ANSI B16.5 Alloy RTJ Flanges

- Alloy 20 BS 4504 Flanges

- Alloy UNS N08020 Flanges Supplier in Mumbai

- Alloy 20 Welding Neck Flanges

- Nickel Alloy 20 304 Slip on Flanges

- Carpenter Alloy 20 Pipe Flanges

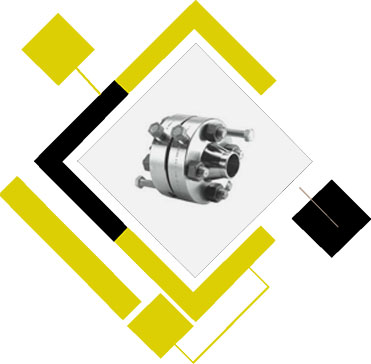

- Incoloy Alloy Orifice Flanges

- Alloy 20 Loose Flanges

- Alloy 20 Raised Face Flanges Stockist

- ASME SB462 Alloy 20 Screwed Flanges

- ASME B16.5 304 Stainless Steel Socket weld Flanges

- ASTM B462 Alloy 20 Flanges

- ASTM B462 Alloy 20 Lap Joint Flanges

- ANSI 20 Alloy Blind Flange

- Alloy 20 BS 4504 Flanges Supplier

- ASTM B462 Alloy 20 BLRF Flange Flanges

- Alloy Male & Female Flanges

- AWWA C207 Flange Manufacturer in Mumbai, India

- ALloy 20 Large Diameter Flanges Exporter

- Alloy 20 Plate Flanges

- NiCr20CuMo Ring Type Joint Flanges

- Alloy 20 High Hub Blind Flanges

- Alloy 20 WNRF Flange

- Alloy 20 Reducing Flanges Price List

- Alloy 20 SORF Flanges

- Carpenter® Alloy 20 Tongue & Groove Flanges

- Alloy 20 Raised Face Flanges

- SAlloy DIN 2.4660 Orifice Flange

- Nickel Alloy 20 SUS 20 Reducing Flanges

- Alloy 20 DIN Flanges

- ASTM B462 Incoloy Alloy Lap Joint Flanges

- Alloy 20 Spectacle Blind Flanges

- Alloy 20 Expander Flanges

- ASTM B462 Alloy 20 SWRF Flange

- Alloy 20 PN 10 Flanges

- ASME SB462 Alloy 20 BLRF Flange Supplier

- Alloy 20 Nippo Flange Manufacturer

Alloy 20 Flanges Export to below Mentioned Countries

MIDDLE EAST : Saudi Arabia, Qatar, Bahrain, Oman, Kuwait, Turkey, Yemen, Syria, Jordan, Cyprus

AFRICA : Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Equatorial Guinea, the Republic Of Congo, Gabon

NORTH AMERICA : US, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark

EUROPE : Russia, Norway, Germany, France, Italy, UK, Spain, Ukraine, Netherlands, Belgium, Greece, Czech Republic, Portugal, Hungary Albania, Austria, Switzerland, Slovakia Finland, Ireland Croatia, Slovenia, Malta

ASIA : Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh,Myanmar, Taiwan, Cambodia

SOUTH AMERICA : Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay